Tungsten Carbide Powder

Tungsten carbide powder is often used to create hardmetals for cutting steel. Once mixed with cobalt and binder, tungsten carbide is pressed and sintered. Sintered tungsten carbide is one of the hardest substances known to man, and is used to cut steel, drill circuit boards and a multitude of other high tech applications in the automobile and aerospace industries, and beyond.

Tungsten Carbide Powder Description:

Tungsten carbide is made up of chemically bonded tungsten and carbide. Its superior hardness enables it to replace steel and other metal alloys in a variety of applications.

Colloquially, tungsten carbide is often simply called carbide. In its most basic form, it is a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery, tools, abrasives, as well as jewelry.

tungsten carbide is approximately four times stiffer than steel, with a Young's modulus of approximately 550GPa, and is much denser than steel or titanium. It is comparable with corundum (a-Al203) in hardness and can only be polished and finished with diamond wheels and compounds.

Tungsten Carbide Powder Typical Application

1) Machine tools Carbide cutting surfaces are often used for machining through materials such as carbon or stainless steel, as well as in situations where other tools would wear away, such as high-quantity production runs. Most of the time, carbide will leave a better finish on the part, and allow faster machining. Carbide tools can also withstand higher temperatures than standard high speed steel tools. The material is usually called cemented carbide, hardmetal or tungsten-carbide cobalt: it is a metal matrix composite where tungsten carbide particles are the aggregate and metallic cobalt serves as the matrix.

2) Military

a) Tungsten carbide is often used in armor-piercing ammunition, especially where depleted uranium is not available or not politically acceptable. The first use of W2C projectiles occurred in German Luftwaffe tank-hunter squadrons, which used 37 mm autocannon equipped Junkers Ju 87G dive bomber aircraft to destroy Soviet T-34 tanks in World War II. Owing to the limited German reserves of tungsten, W2C material was reserved for making machine tools and small numbers of projectiles for the most elite combat pilots, like Hans-Ulrich Rudel. It is an effective penetrator due to its high hardness value combined with a very high density.

b) Tungsten carbide ammunition can be of the sabot type (a large arrow surrounded by a discarding push cylinder) or a subcaliber ammunition, where copper or other relatively soft material is used to encase the hard penetrating core, the two parts being separated only on impact. The latter is more common in small-caliber arms, while sabots are usually reserved for artillery use.

c) Tungsten carbide is also an effective neutron reflector and as such was used during early investigations into nuclear chain reactions, particularly for weapons. A criticality accident occurred at Los Alamos National Laboratory on 21 August 1945 when Harry K. Daghlian, Jr. accidentally dropped a tungsten carbide brick onto a plutonium sphere, causing the sub-critical mass to go critical with the reflected neutrons.

3) Sports

a) Hard carbides, especially tungsten carbide, are used by athletes, generally on poles which impact hard surfaces. Trekking poles, used by many hikers for balance and to reduce pressure on leg joints, generally use carbide tips in order to gain traction when placed on hard surfaces (like rock); such carbide tips last much longer than other types of tips.

b) While ski pole tips are generally not made of carbide, since they do not need to be especially hard even to break through layers of ice, rollerski tips usually are. Roller skiing emulates cross country skiing and is used by many skiers to train during warm weather months.

c) Sharpened carbide tipped spikes (known as studs) can be inserted into the drive tracks of snowmobiles. These studs enhance traction on icy surfaces. Longer v-shaped segments fit into grooved rods called wear rods under each snowmobile ski. The relatively sharp carbide edges enhance steering on harder icy surfaces. The carbide tips and segments reduce wear encountered when the snowmobile must cross roads and other abrasive surfaces.

d) Some tire manufacturers, such as Nokian and Schwalbe, offer bicycle tires with tungsten carbide studs for better traction on ice. These are generally preferred over steel studs because of their wear resistance.

4) Domestic

a) Tungsten carbide is sometimes used as the rotating ball in the tips of ballpoint pens to disperse ink during writing.

b) Tungsten carbide can now be found in the inventory of some jewelers, most notably as the primary material in men's wedding bands. When used in this application the bands appear with a lustrous dark hue often buffed to a mirror finish. The color is more similar to that of hematite than to that of platinum. The finish is highly resistant to scratches and scuffs, holding its mirror-like shine for years, although many jewelers are now able to inlay precious metals, woods, and other materials into tungsten carbide rings, which may not be as scratch-resistant as the tungsten carbide portions of the jewelry.

c) A common misconception held concerning tungsten carbide rings is they cannot be removed in the course of emergency medical treatment, requiring the finger to be removed instead. Emergency rooms and many full-service jewelry repair shops are equipped with jewelers' saws that can cut through tungsten carbide rings without injuring the hand or finger. An easier way to remove tungsten carbide rings is to use a tool such as vice grip style locking pliers.

d) Many manufacturers of this emerging jewelry material state that the use of a cobalt binder may cause unwanted reactions between the cobalt and the natural oils on human skin. Skin oils cause the cobalt to leach from the material. This is said to cause possible irritation of the skin and permanent staining of the jewelry itself. Many manufacturers now advertise that their jewelry is "cobalt free". This is achieved by replacing the cobalt with nickel as a binder.

Specification:

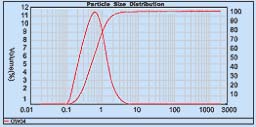

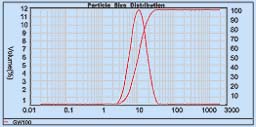

Ultra-fine and sub-micro powder

GWC04 X7000

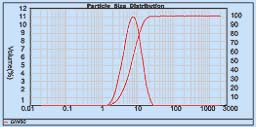

1μ to 9μ powder

GWC60 X1200

Coarse powder

GWC100 X1000

Packing: in plastic bag with outer iron drums of 50/100kgs net each.

If you have any interest in our products, please feel free to contact us by email: sales@chinatungsten.com or by telephone:

+86 592 5129696.

sales@chinatungsten.com;

sales@chinatungsten.com;